Summary

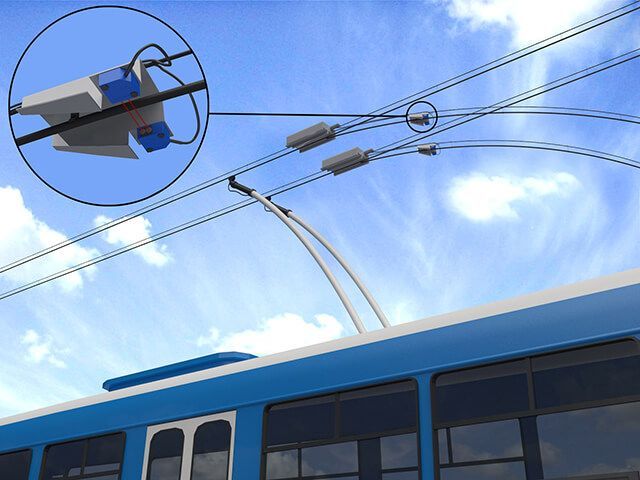

When a trolley bus reaches a road junction, wire-switches, installed on the overhead conductor cables, control its direction of travel. Switches may be in the default “straight-through” position or in “turnout” position. As a bus passes a switch in turnout position, a sensor mounted on the overhead cables detects the presence of the current collector. The control system then resets the switch to the default position.

Customer Values

- Exceptional reliability in a harsh outdoor environment

- Automatic operation with optimal space utilization

- Elimination of switching errors during year-round operation

- Significantly reduced maintenance costs

Specific Product Advantages

- All-electronic device with sensing range up to 12,000 mm

- Large sensing range available in physically small sensor

- Exceptional resistance to vibration during operation.

Customer Application

In many countries, public-transit operators run fleets of trolley buses in major towns and cities. At road junctions, wire-switches, installed on the overhead conductor cables, control the direction of travel. Switches default to the straight-through position. When a bus approaches a turn, the driver uses a remote trigger to change the switch to the turnout position; after the bus completes the turn, the switch reverts to the straight-through position.

If a triggered switch reverts to the straight-through position prematurely, the current collector may become disengaged, damaging the switch. Operators install safety systems to prevent premature switching. Typically, these utilize timer circuits that introduce a predetermined delay or mechanical sensors that rely on physical contact with the current collector. Neither system is sufficiently reliable.

A Swiss manufacturer of trolley-bus control systems requires a highly reliable, rugged sensor system that will detect the presence of a current collector as it passes a switch. The system must operate with minimal maintenance and withstand the varied weather conditions of an outdoor environment.

Customer Solution

Highly stable, all-electronic through-beam sensors from the Contrinex photoelectric range provide a reliable and cost-effective alternative. A purpose-designed metal bracket, mounted above the conductor cable, holds the transmitter and receiver units in alignment on either side of the cable. As the current collector passes between the two units it breaks the beam, triggering the sensor and returning the switch to the straight-through position.

The molded-resin sensor casings, fitted with glass sensing faces, are rated to IP67, making them virtually impervious to the harsh, outdoor environment. Physically small housings (30x30x15mm) eliminate the risk of accidental damage arising from a mechanical collision. Additionally, the bracket, complete with sensor, occupies a minimal amount of space in the crowded overhead area. Rugged construction and vacuum-encapsulated electronics minimize the effects of vibration.

Each unit is connected to the trolley-bus control systems via a PVC-sheathed cable with a hermetically sealed entry. The receiver has an industry-standard PNP dark-on interface. The one-piece mounting bracket allows easy removal and replacement of the complete assembly during routine maintenance. Operational results have been excellent. The new Contrinex sensors are highly reliable, eliminating switching errors and reducing maintenance costs significantly.