Summary

Safe, reliable control of weathertight doors is essential for shipbuilders. Doors rest against compressible seals; double-acting hydraulic cylinders open and close multiple latches that secure the doors. Designers require a means of confirming the status of latches, capable of withstanding the aggressive marine environment. DNV-GL-approved High-Pressure inductive sensors from Contrinex, embedded into each cylinder, are sea-water resistant, providing a cost-effective solution that delivers proven reliability.

Customer Application

Safe, reliable control of weathertight doors and hatches is a must for shipbuilders in every area of marine engineering. As well as safeguarding the lives of passengers and crew, marine doors protect sensitive equipment from water damage – a particular concern in the defense sector where highly specialized systems are not easily replaceable in the event of failure.

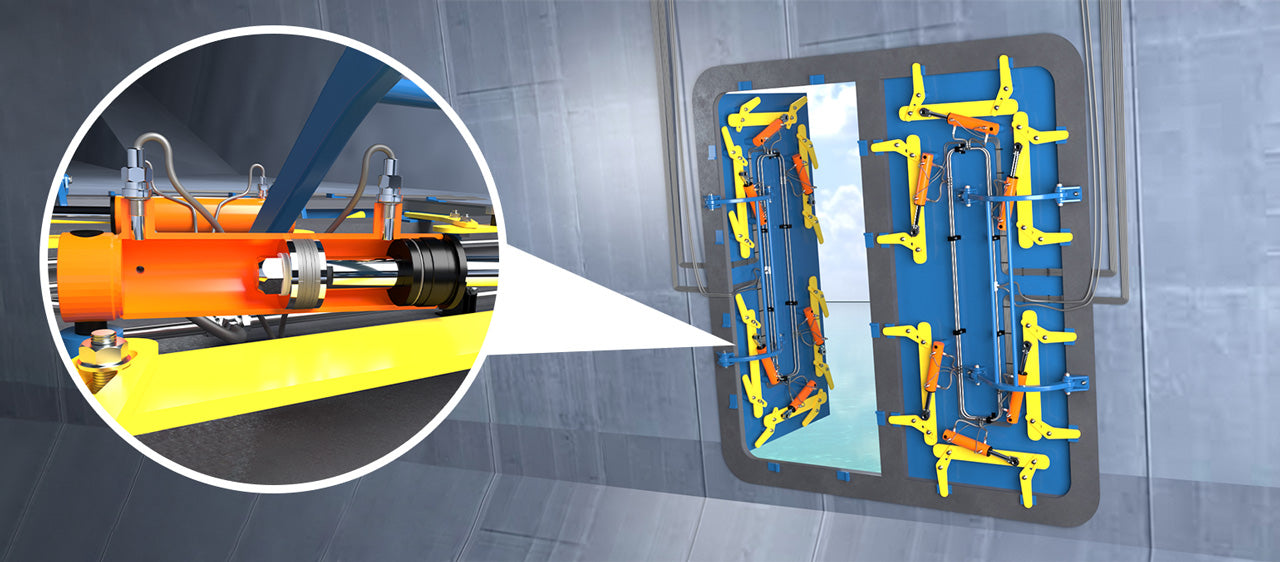

Typically, designers still rely on tried-and-tested methods to ensure watertight operation. When closed, the outer edge of a door rests against a compressible seal; the door is held in place by a number of latches around its periphery. Each latch rotates into position, compressing the seal as it does so.

Modern vessels use mechanized control systems to lock and unlock doors and hatches, often relying on double-acting hydraulic cylinders to engage and disengage one or more latches. Engineers require a highly durable, robust means of sensing the position of each cylinder, thus confirming the status of the latches under its control. The sensing system must be fit for continuous use in a highly aggressive marine environment, offering proven reliability with minimal maintenance.

A leading cylinder manufacturer in the marine sector specified DNV-GL-approved High-Pressure inductive sensors from specialist Swiss manufacturer Contrinex, embedding two sensors into each cylinder. Rated to IP68/IP69K, these M12 devices feature one-piece V4A (AISI 316L) stainless-steel housings and operate at continuous pressures up to 500 bar.

Customer solution

Each sensor is positioned immediately adjacent to the cylinder ram, one at each extreme of travel, comfortably withstanding the internal cylinder pressure. A sensing distance of 1.5 mm ensures eliminates the risk of any accidental damage during operation, while the sensor construction not only ensures excellent resistance to aggressive environments, but also exceptional tolerance of vibration and mechanical shock.

Connection to the local control system is via a 10-meter PUR 3-core cable, while an industry-standard PNP normally-open interface ensures ease of integration. The sensors withstand ambient operating temperatures in the range -25oC to +85oC, suitable for even the harshest weather conditions.

IO-Link connectivity provides an easy alternative interface to a central control system for routine process data. During initial calibration, each sensor’s configuration is stored automatically on the local IO-Link Master; this allows plug-and-play replacement of sensors should the need arise, without any loss of functionality and without any need for recalibration.

Approved to the DNVGL-CG-0339 environmental test specification for equipment to be installed on ships and offshore units, these sensors are ideal for the application. They are sea-water resistant and satisfy fully the requirement for continuous use in a highly aggressive marine environment. This is a cost-effective solution that delivers proven reliability together with complete peace of mind.

Customer benefits:

- Rugged DNV-GL-approved High-Pressure inductive sensors deliver reliable position sensing in extreme environments

- Embeddable sensors operate at continuous pressures up to 500 bar, allowing direct sensing of cylinder rams

- Full-Inox construction ensures sea-water resistance plus exceptional tolerance of vibration and shock

- Proven technology ensures highly reliable fit-and-forget operation with minimal manual intervention

- Rated to IP68/IP69K, Contrinex sensors offer a cost-effective solution that delivers complete peace of mind.

Product Specific Advantages:

- Approved to the DNVGL-CG-0339 environmental test specification for equipment to be installed on ships and offshore units

- Sensor performance unaffected by 500 bar (7255 psi) operating pressure

- Small, lightweight embeddable sensors with IP68/IP69K sea-water-resistant construction

- Robust, full-Inox inductive Sensors are ideal for easy integration

- Industry-standard IO-Link interface offers multiple sensing options at no extra cost

- Excellent -25°C to +70°C operating range