Summary

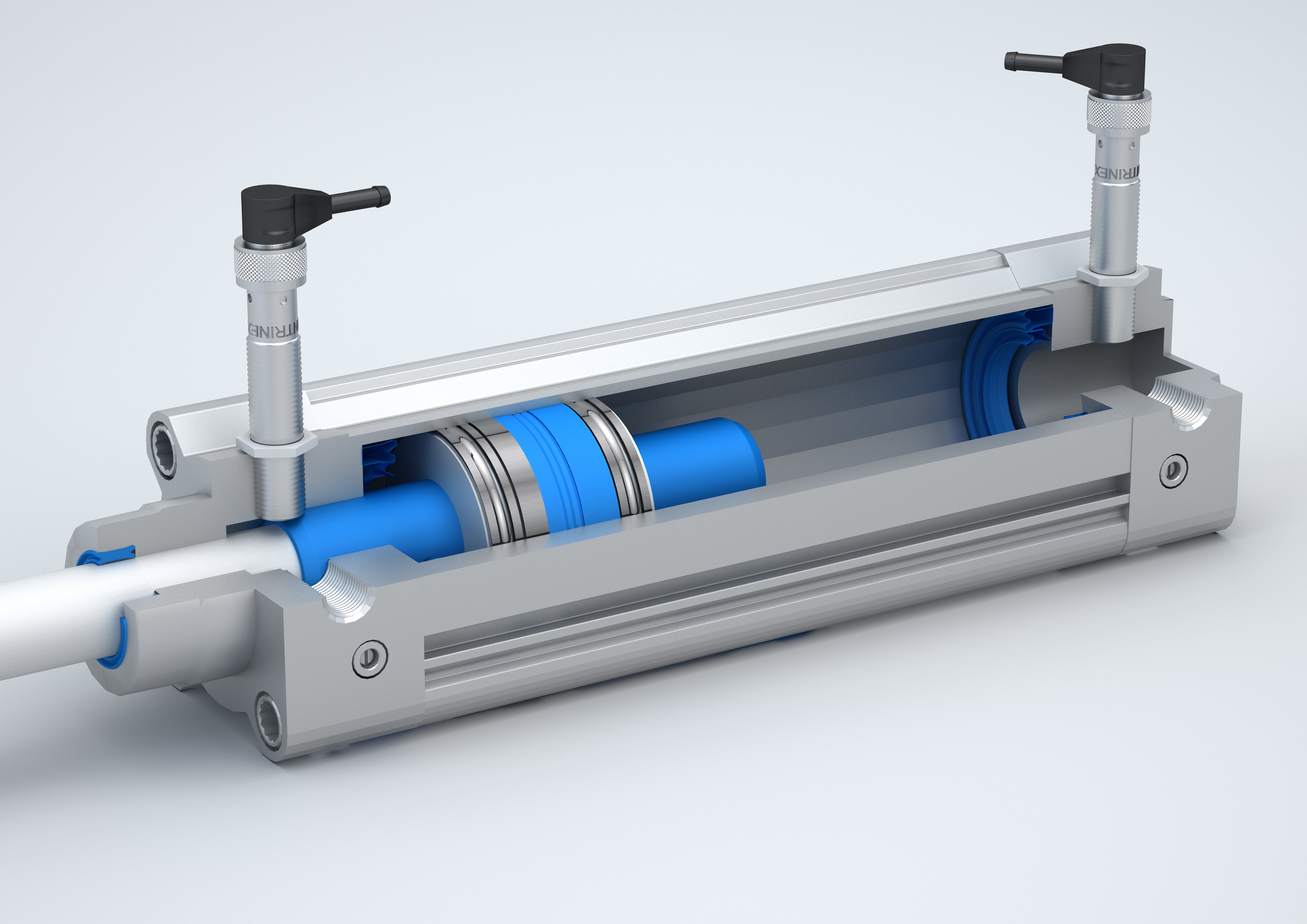

Industrial equipment designers continually seek ways to reduce cycle times without compromising safety or increasing cost. Engineers require a monitoring capability for pneumatic cylinders that identifies deviations from the optimal deceleration profile without increasing complexity or cost. Rugged, multi-mode Smart Sensors from Contrinex, embedded in each cylinder, identify adverse trends in the deceleration profile, providing a cost-effective, unobtrusive fit-and-forget solution.Customer Values

-

Embeddable inductive Smart Sensors offer multiple sensing modes in a single device, eliminating increased complexity and cost

-

The Smart Sensor’s one-shot timer feature allows process engineers to identify deviations from the optimal deceleration profile, minimizing maintenance expense

-

The Smart Sensor’s dual-channel capability enables a local alarm to be triggered by an event-based exception, avoiding a plant-wide shut-down

-

Industry-standard IO-Link connectivity provides a single interface to the machine control system

-

Cumulative operating data for predictive maintenance, including temperature and operating-cycle count, is recorded in on-board data storage

-

Sensor configurations are stored locally, allowing plug-and-play replacement of sensors when needed

-

Proven technology ensures highly reliable fit-and-forget operation with no manual intervention

Specific Product Advantages

-

Robust, metal-cased inductive Smart Sensors are ideal for easy integration

-

Multi-channel monitoring circuitry allows users to define up to nn customized output thresholds

-

Sophisticated sensing electronics deliver high-precision multi-mode measurements

-

High-speed device-to-device communication enables decentralized data-processing and decision making

-

Smart Sensors are individually shielded and EMC immune, eliminating interference when multiple devices operate in close proximity

-

Dedicated service-data blocks hold device-specific data including product ID, location and serial number

-

Visible LED indicators enable sensors to self-identify on demand, simplifying commissioning and trouble-shooting routines

-

Industry-standard -25°C to +70°C operating range