Summary

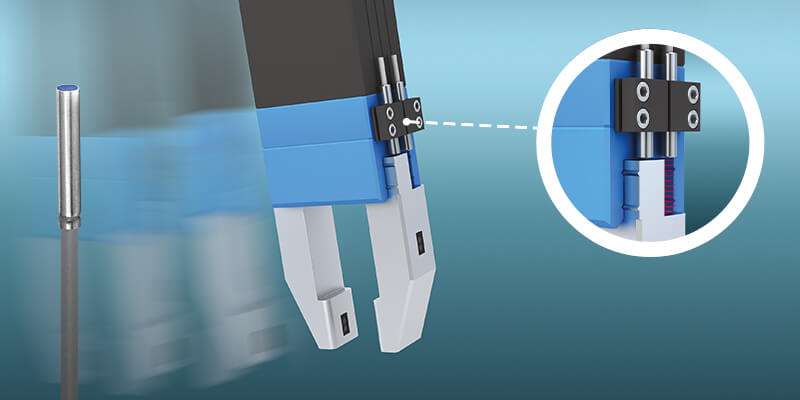

During automated production of solar cells, compact two-finger robot edge-grippers transport trays of silicon wafers between operations. To avoid impacts on the wafers surfaces, process engineers require reliable confirmation that gripper jaws are fully open before the gripper descends to pick up a tray. Ultra Miniature inductive proximity sensors, mounted directly above the top faces of the gripper fingers, sense the position of the jaws in the fully open position, eliminating avoidable scrap costs.

Customer Value

- Embedded miniature distance sensors ensure reliable detection of potential obstructions, eliminating collision hazards

- Compact 3mm-diameter × 22mm V2A stainless-steel housing allows easy integration in tight spaces

- Sensing distance of 1mm offers designers attractive alternatives when specifying equipment

- Industry-standard PNP and NPN outputs with normally open or normally closed options interface easily with a wide range of control systems

- Proven technology ensures highly reliable fit-and-forget operation with no manual intervention

- Non-contact solution maintains production throughput and eliminates avoidable scrap costs

Specific Product Benefits

- Miniature stainless-steel inductive proximity sensors suitable for easy integration

- PNP and NPN interface with NO and NC options and minimal power consumption

- Sensor weight only 25 grams with a compact 3mm-diameter × 22mm housing

- Industry-standard −25°C to +70°C operating range

- Reliable, compact vibration-resistant sensors