Summary

During high-volume confectionery packaging operations, conveyors deliver stacked cartons to shrink-wrapping stations. At each station, a wrapping machine encloses a stack in heat-shrink film and an infrared oven shrinks the film to form a sealed pack of cartons. A long-distance through-beam photoelectric sensor, mounted beside the conveyor, senses the presence of each pack as it leaves the oven and signals a plant-wide control system to increment the production throughput totals.

Customer value

- Reliable long-range item counting on a non-contact basis

- Improved data accuracy arising from real-time, error-free pack detection

- Increased productivity as stability alarm flags preventative-maintenance needs

- Single sensor accommodates a range of carton sizes without repositioning

Specific product advantages

- Maximum sensing range of 30,000 mm

- IO-Link connectivity available at no extra cost on PNP versions

- Dual output with stability alarm

- Versatile, purpose-designed mounting brackets for ease of installation

- Mutual interference immunity by setting emitter/receiver pairs via IO-Link

Customer Application

In factories producing fast-moving consumer goods, automated packaging operations are the norm. Confectionery products are no exception; in high-volume production, manufacturers pack sealed bags of candy in cardboard cartons, which are in turn stacked for shrink- wrapping and palletization.

Packed cartons arrive for shrink-wrapping in uniform stacks. A wrapping machine encloses each stack in a tube of heavy-duty heat-shrink film; the stack then passes through an infrared oven, where the film shrinks, forming a sealed pack of cartons. After heat-shrinking, packs are conveyed to the consolidation area for palletization.

Factory operators need to monitor production throughput for each packaging line. Manual counting methods are impractical and expensive. A highly reliable non-contact sensor system is needed to detect the presence of each pack as it leaves the shrink-wrapping area and to update the item count held on a plant-wide control system. Long-distance operation is desirable, as not all packaging lines are easily accessible.

Customer Solution

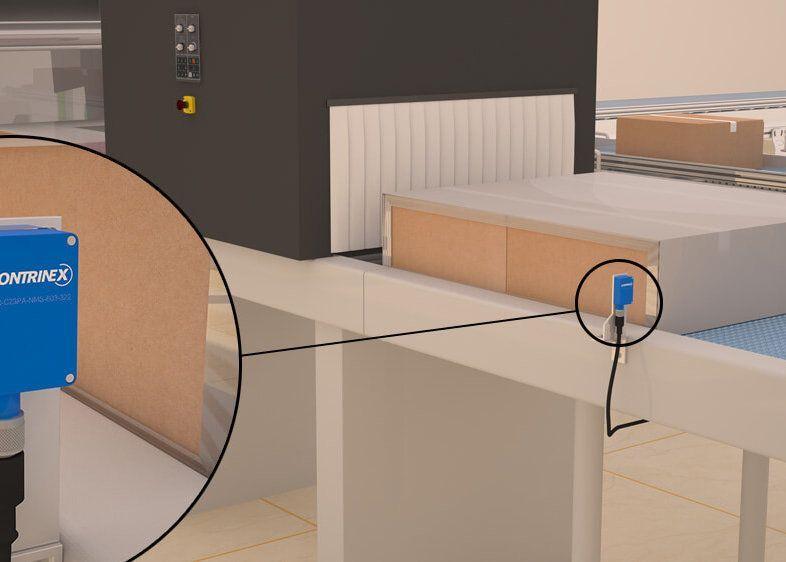

Miniature through-beam photoelectric sensors from the Contrinex C23 range are ideal for this application. These dual-unit sensors, available with an optional alignment aid, have a maximum sensing range of 30,000mm. Each sensor comprises a separate transmitter and receiver, each mounted in a 20mm x 30mm x 10mm miniature plastic housing; connection to the control system is via a PVC-sheathed cable with the choice of an integral M12 connector or a hermetically sealed entry.

Immediately after each oven, a sensor is mounted with the transmitter and receiver on opposite sides of the conveyor. Depending on the space available around the oven, either unit may be located some distance away from the track. The integral alignment aid ensures rapid, accurate set-up, even at extremes of operating range, while custom-designed mounting brackets allow optimal sensor positioning in almost any situation.

As each carton breaks the light beam, the sensor detects its presence and signals the control system to increment the item count. Industry-standard PNP or NPN 3‑wire or 4-wire outputs support direct interfacing with modern industrial controls. A second output provides a stability alarm in the event of reduced sensitivity, flagging the need for preventative maintenance before any performance degradation occurs.

The C23 range detects fast-moving targets reliably; remote selection of switching frequency is possible via IO-Link, a standardized point-to-point serial connection protocol, available as standard at no extra cost for PNP versions.