Summary

Smart inductive sensors provide automation engineers with affordable high-precision position-control options for linear stages

Automation engineers designing high-speed assembly equipment with multiple linear transfers between workstations need to maximize speed and accuracy while keeping cost down. They require a single-sensor positional-control solution that delivers a high-speed approach to the critical areas and a slower, high-precision final positioning. Designers specified inductive Smart Sensors from Contrinex; a single sensor with IO-Link connectivity and multiple user-configurable outputs performs both the required tasks in a highly cost-effective manner.

Customer Values

-

Rugged inductive Smart Sensors ensure accurate positioning of linear stages without compromising operational speed

-

Single-sensor positional-control system is non-complex and highly affordable

-

Compact embeddable M12 sensors fit unobtrusively and easily into off-the-shelf linear guide rails

-

Industry-standard IO-Link connectivity provides a single interface to the machine control system.

-

Sensor configurations are stored locally, allowing plug-and-play replacement of sensors when needed.

-

Proven technology ensures highly reliable fit-and-forget operation with no manual intervention

Specific Product Advantages

-

Robust, metal-cased inductive Smart Sensors are ideal for easy integration

-

Multi-channel monitoring circuitry allows users to define up to nn customized output thresholds

-

Sophisticated sensing electronics deliver dynamic linear-distance measurements with a resolution in the micron range

-

On-board data storage holds cumulative operating data for user-specified purposes, including predictive maintenance

-

High-speed device-to-device communication enables decentralized data-processing and decision making

-

Dedicated service-data blocks hold device-specific data including product ID, location and serial number

-

Visible LED indicators enable sensors to self-identify on demand, simplifying commissioning and trouble-shooting routines

-

Industry-standard -25°C to +70°C operating range

Customer Application

Automation engineers often face a three-way balancing act when designing equipment, trying to maximize speed and accuracy while keeping cost at acceptable levels. Position control is no exception – high-performance systems typically rely on linear or rotary encoders to deliver the required positional accuracy, and these can be expensive, particularly when both coarse and fine positioning are needed.

Using a secondary sensor for coarse-positional control is a commonly used, although inelegant, solution to the problem. It also increases complexity and cost, while reducing the overall reliability of the system. Alternatively, designers maintain accuracy without increasing cost by reducing travel speeds during coarse positioning, increasing the cycle time. Neither approach is optimal.

Equipment manufacturers (OEMs) specifying high-speed assembly equipment with multiple linear transfers between workstations need an alternative solution. Using off-the-shelf linear stages, they require a controlled, fast approach to the critical areas and a slower, high-precision final positioning – without increasing complexity or cost. An affordable single-sensor solution is highly desirable.

Customer Solution

Designers specified rugged inductive sensors from the Contrinex Smart Sensor portfolio; a single sensor with IO-Link connectivity and multiple user-configurable outputs performs both the required tasks. Firstly, it initiates a controlled deceleration as the carriage of a linear stage approaches the specified workstation; it then switches to micrometer distance resolution, positioning the stage accurately and precisely.

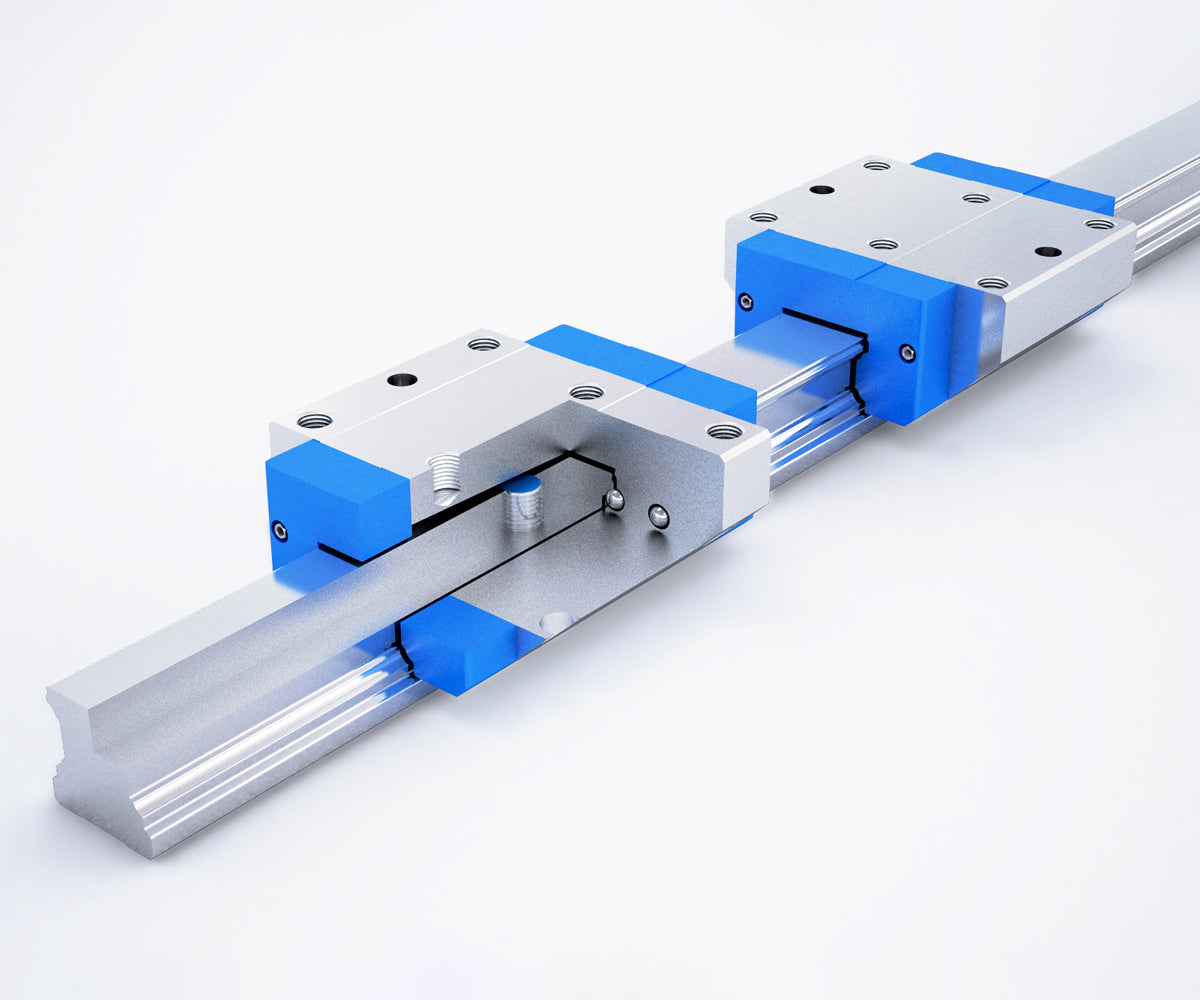

Contrinex inductive Smart Sensors are designed with the needs of OEMs and system integrators in mind and provide an unobtrusive fit-and-forget solution. A single metal-cased M12 sensor is embedded in one of the guide rails immediately adjacent to each workstation. The sensor detects the presence of the carriage as it begins to pass overhead, triggering the deceleration and changing the sensing mode.

The sensor now operates as a high-precision distance-measurement device; its target is an inclined face on the underside of the carriage. As the carriage moves over the sensor, the distance to the inclined faces changes in direct proportion to the distance moved. With a sensing distance of up to 6 mm and a dynamic resolution of ±5.5 micrometers, the sensor delivers a highly accurate nn-bit digital output, enabling the carriage position to be determined in real time.

Once the initial set-up is completed, each sensor’s configuration is stored automatically on the local IO-Link Master; this allows plug-and-play replacement of sensors should the need arise, without any loss of functionality and without any need for recalibration. These highly versatile sensors meet designers’ needs for a highly reliable, cost-effective and non-complex solution without compromising operational performance.