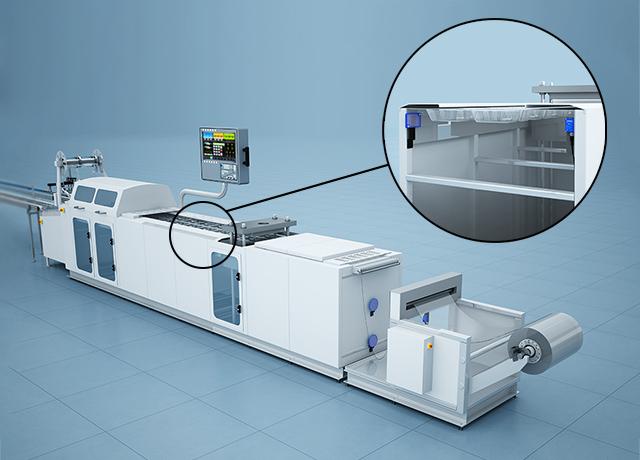

Transparent-object sensors with patented UV technology ensure reliable detection and accurate counting of clear plastic trays

During automated packaging of fast-moving products in controlled conditions, thermoforming lines produce transparent plastic tray bases from continuous reel-stock material. A small transparent-object sensor with patented UV technology detects the presence of each set of transparent trays after it is formed, initiating a subsequent operation and, optionally, triggering a counting circuit. Manual intervention is avoided, ensuring contamination-free, reliable operation with little or no downtime.

Customer value

• UV sensors ensure reliable detection of transparent, irregularly shaped plastic targets

• Safe detection of the thinnest transparent materials

• Maximum operating reserve owing to high absorption factor of UV light by transparent plastics

• Elimination of multiple switching on a single target

• Reliable operation without the need for manual intervention

• Very low sensitivity to dust, liquid droplets and splashes

• Wide operating range accommodates full range of machine geometries

• Simple one- or two-step teach procedure optimizes initial sensor set-up

• Sensitivity parameters are retrieved or updated remotely via IO-Link

• Stability alarm highlights reduced sensitivity, avoiding unplanned stoppages

Specific product advantages

• Ultraviolet reflex photoelectric sensors for transparent object detection

• Very low sensitivity to target shape

• IO-Link serial-connection protocol enabled on PNP versions at no additional cost

• Pre-taught sensitivity parameters stored on inbuilt sensor memory

• Remote sensitivity retrieval or update via IO-Link

• Highly tolerant of contamination by dust, liquid droplets or splashes

• Robust, Ecolab approved sensors with IP67-rated small plastic housings