In marine engineering, the safe and reliable operation of weathertight doors and hatches is critical. These systems protect passengers, crew, and valuable onboard equipment from water ingress, particularly in demanding applications such as naval and offshore vessels. Ensuring that each door is correctly latched and sealed requires robust sensing technology capable of operating in extreme conditions.

Contrinex High-Pressure Inductive Sensors provide a dependable solution for monitoring the position of hydraulic cylinders used to actuate door latches, delivering precise feedback even in aggressive marine environments.

Application Challenge

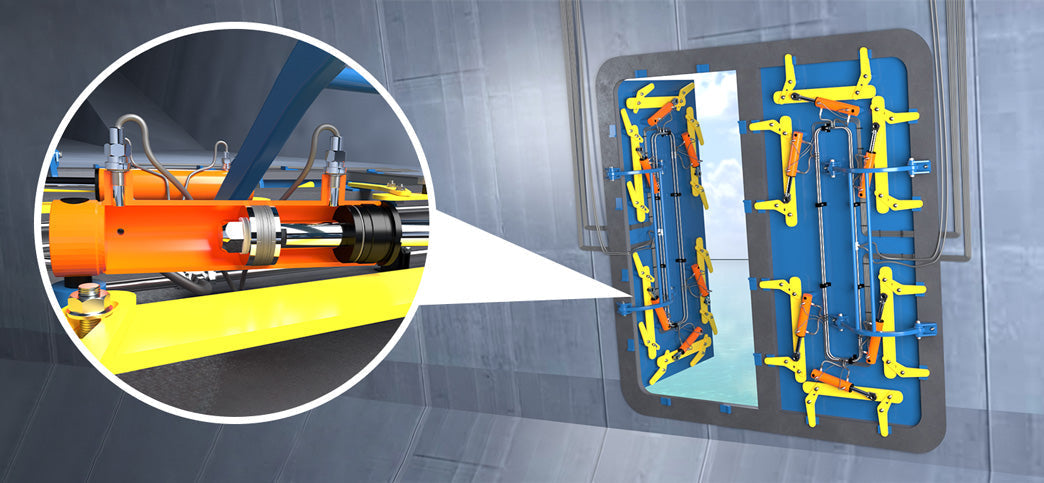

Watertight doors are typically secured using compressible seals and multiple latches positioned around the door perimeter. Modern vessels increasingly rely on automated systems to control these latches, often using double-acting hydraulic cylinders to engage and disengage them.

To guarantee proper sealing, engineers must be able to confirm the exact position of each cylinder and, therefore, the status of every latch. The sensing solution must withstand:

- Continuous exposure to saltwater and humidity

- High mechanical stress and vibration

- Wide temperature fluctuations

- Hydraulic pressures of up to 500 bar

Reliability and minimal maintenance are essential, as access for servicing is often limited.

Sensor Solution

A leading marine cylinder manufacturer selected DNV-approved Contrinex High-Pressure Inductive Sensors for direct integration into their hydraulic cylinders. Two sensors are embedded per cylinder, positioned at each end of the ram’s travel to confirm fully open and fully closed latch positions.

Key technical features include:

- IP68/IP69K protection rating

- One-piece V4A (AISI 316L) stainless-steel housing

- Continuous operating pressure up to 500 bar

- Sensing distance of 1.5 mm to prevent mechanical contact

- High resistance to vibration, shock, and corrosion

This design enables accurate position detection while ensuring long-term durability in harsh operating conditions.

System Integration

The sensors connect to the local control system via a 10 m PUR 3-core cable and use an industry-standard PNP normally-open output for straightforward integration. IO-Link communication provides an additional interface for diagnostics and process data transmission.

During commissioning, each sensor’s configuration is automatically stored on the IO-Link master. In the event of sensor replacement, plug-and-play functionality allows immediate operation without recalibration, minimizing downtime and maintenance effort.

The sensors operate reliably across an ambient temperature range from -25°C to +85°C, making them suitable for deployment in diverse marine climates.

Compliance and Performance

Approved to the DNV-CG-0339 environmental test specification for equipment installed on ships and offshore units, Contrinex sensors meet stringent marine certification requirements. Their seawater-resistant construction and pressure-tolerant design ensure consistent performance throughout the service life of the system.

Customer Benefits

- Reliable position sensing for hydraulic door latches in extreme marine environments

- Continuous operation at pressures up to 500 bar

- Full stainless-steel construction for superior corrosion resistance

- High tolerance of vibration and mechanical shock

- Fit-and-forget operation with minimal maintenance

- Cost-effective solution delivering long-term reliability

Product Advantages

- Certified to DNV-CG-0339 marine environmental standards

- Performance unaffected by hydraulic pressure

- Compact, embeddable sensor design

- IP68/IP69K seawater-resistant housing

- IO-Link interface included as standard

- Operating temperature range from -25°C to +70°C

Conclusion

The use of Contrinex High-Pressure Inductive Sensors in hydraulic latch systems enables shipbuilders to achieve reliable, verifiable control of weathertight doors and hatches. By combining certified marine compliance with proven sensing technology, this solution provides dependable operation in one of the world’s most demanding environments—ensuring both safety and system integrity at sea.